Engineering Services

Are you struggling with off-the-shelf gearing solutions that have excessive backlash, noise, short lifespans, or large footprints? All are problems that RJ Link International, Inc. can solve with our engineering services.

Are you struggling with off-the-shelf gearing solutions that have excessive backlash, noise, short lifespans, or large footprints? All are problems that RJ Link International, Inc. can solve with our engineering services.

RJ Link’s engineering team utilizes industry leading software to deliver top tier performance.

Consultation & Needs Assessment

During our initial project consultation our goal is to gain a deep understanding of our customer’s requirements and challenges in order to gain a better understanding of the customer’s concerns.

Design & Simulation

Utilizing KISSsoft gear design software, existing gears can be reverse engineered or new gears are designed.

- KISSsoft provides in-depth gear tooth interaction simulation allowing for optimal gear geometry.

- KISSsoft also provides full system analysis based on gear design. Allowing the gears, shafts, and bearings to all work together.

Validation & Integration Support

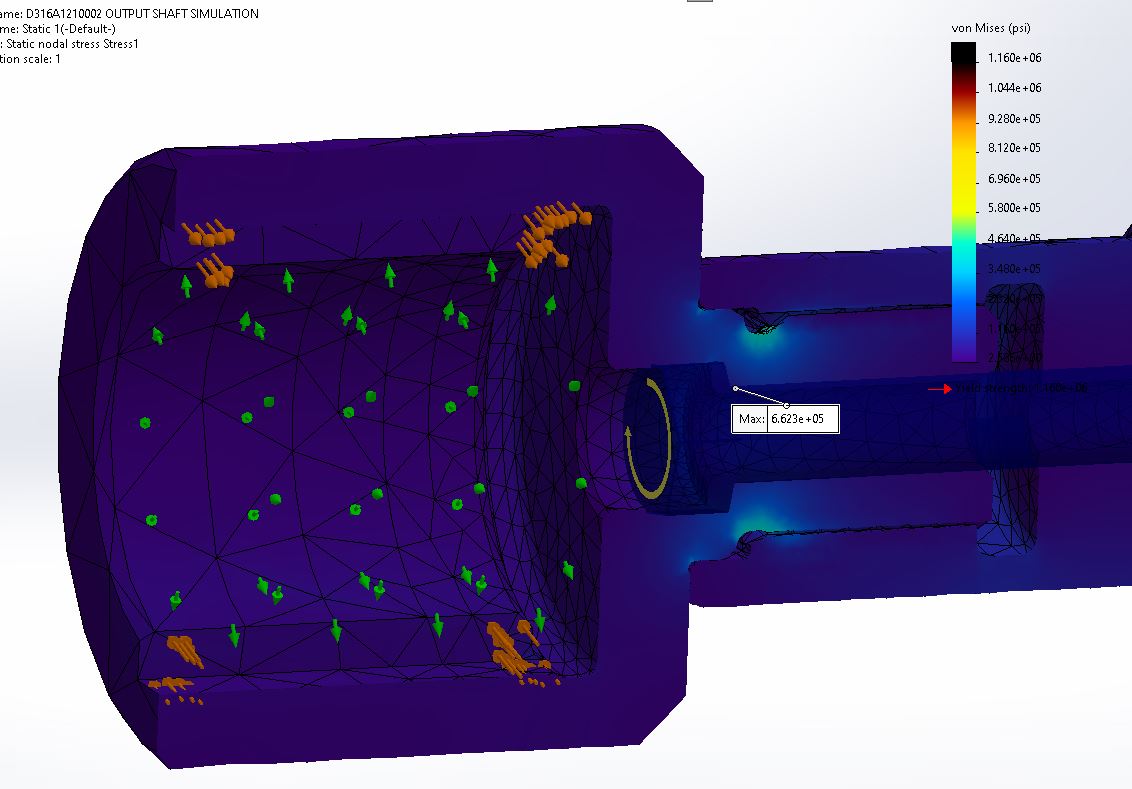

Utilizing Solidworks with Finite Element Analysis (FEA) analysis we are able to wrap the gearset in the most space efficient housing.

- 3D models are provided to support integration into the customer’s machine design.

Our engineering support services are tailored to our customer's needs from start to finish

Support Services Include:

- Custom Gearbox Design & Build Services

- Gearbox Repair and Remanufacturing

- Finite Element Analysis (FEA)

- Prototyping & Validation Services

- Gear Sizing Software and Analysis

- Fixture and Tooling Design

- Process Design

- PPAP’s (Preproduction Approval Process)

- Program Management

- Reverse Engineering

- Technical Documentation Support

- Inspection – Coordinate Measurement Machine (27in. x 40 in. x 24in.)

- Inspection – CNC Gear Inspection (Dia. 11.5in. x length 23.5in.)

- Rj Link Oil Recommendations – Contact factory for information

- Gearbox Application Data Sheet

Our Gearbox Expertise Includes:

- Design and manufacture all types of gearbox assemblies; Speed Increasers, Speed Reducers, Transfer Cases, Right Angle and Planetary Gearboxes.

- Providing expertise in the remanufacturing and overhaul of gearboxes.

- Gear grinding: Up to 15.74″ diameter. AGMA class 5 per the new AGMA 2015 inspection standard. Previously considered AGMA class 12 per the old AGMA 1000-A88 standard.

- Alliances with local manufacturers having gearing experience allows us to offer our customers major OEM experience with small company responsiveness.

CAD Platforms:

- Solidworks

FAQs

Is my project too small?

Absolutely not! RJ Link works with customers of all sizes. We are just as happy to sell 1 gearbox as 100 gearboxes.

How quickly can a project be complete?

Project lead time vary greatly depending on current manufacturing load and scope of the project. Typical lead time ranges from 20-52 weeks.

What information is needed to get started?

More information is always better. Ideally knowing the input Hp, input RPM, output Hp, output RPM, and rotation orientation is the minimum. Pictures are always a welcome sight as well.

Do I need to purchase the parts/gearbox from RJL?

No, while RJ Link has significant manufacturing capabilities; we understand some customer prefer to work with their local trusted manufacturers.

Contact Us Today

Reach out to learn how we can help by providing our Engineering Services capabilities to your next project